The Stanley Tumbler has recently become a popular and trendy product!

Enthusiastic fans are crazily rushing to purchase it, with some going to extremes like braving the cold winds to squat in parking lots, queuing overnight, and even jumping onto sales counters to grab one.

The limited edition “Winter Pink” cup, originally priced at $49.95, was launched a few days ago and was once inflated to $300! However, this highly sought-after product has recently been exposed to contain lead, which may have potential health effects.

Do Stanley Cups Contain Lead?

According to NBC News, a spokesperson for Stanley responded to the allegations, stating that the bottom of the Stanley tumbler is made up of circular stainless steel pieces covering small round balls, and these balls contain lead components.

The function of these small round balls is to seal the vacuum insulation of the cup. As long as the stainless steel pieces do not detach, the small round balls cannot be exposed, ensuring there is no lead leakage and poisoning risk. The spokesperson emphasized that cases of stainless steel pieces detaching are extremely rare.

Lead based solder is still used in almost all insulated water bottles on the market. Solder is the material used to seal in the vacuum layer into your steel water bottles. It is found at the base of every insulated stainless steel water bottle. During the vacuumization process this material melts to seal in the vacuum layer to the insulated bottle.

Health Effects of Lead

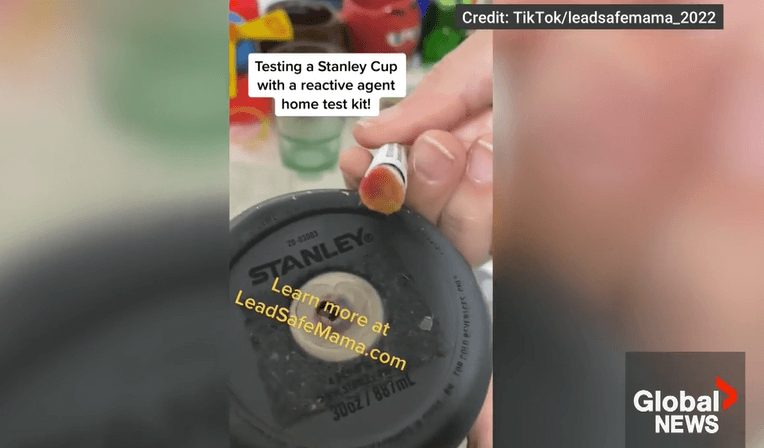

Some social media users have shared videos of conducting lead tests on these cups at home. In the videos, some testers reported positive results for lead content.

However, it is currently unclear which part of the cup these home tests specifically detected and the methods used for the testing.

Tamara Rubin, an anti-lead poisoning expert known as the “Lead Safe Mama,” utilized X-ray Fluorescence (XRF) technology to test several Stanley stainless steel cups with peeling bottoms, and indeed found lead leakage.

She stated, “While some say that this protective ring is not easy to come off, I have heard many people say that theirs has already come off.”

Factors such as prolonged or frequent use of the cup, children playing with the cup’s bottom, and repeated cleaning may increase the likelihood of the protective layer coming off. She expressed concern that in the case of stainless steel cups with peeling bottoms, when children touch their mouths or noses after playing, lead particles are “likely” to enter the body.

Lead-containing Welding Materials VS Lead-free Welding Materials

The welding materials for stainless steel water bottles involve two options: those containing lead and those without lead, which significantly differ in terms of product safety and environmental impact.

Lead-containing Welding Materials:

Lower Cost: Welding materials containing lead generally have lower costs, potentially leading to an overall reduction in product costs.

Ease of Processing: Lead-containing welding materials are usually easier to process during manufacturing, contributing to increased production efficiency.

However, lead-containing materials also come with some drawbacks:

Health Risks: Lead is a toxic substance, and prolonged exposure can have adverse effects on human health, especially when hot liquids come into contact with the lead-containing parts of the cup, potentially leading to lead leaching.

Lead-free Welding Materials:

Environmentally Friendly: Lead-free welding materials are more environmentally friendly, as they do not contribute to lead pollution.

Safety: Lead-free options align better with food safety standards, reducing health risks associated with lead.

Yet, lead-free materials also present some challenges:

Higher Cost: Lead-free welding materials generally have higher costs, which may be reflected in the product’s retail price.

Processing Difficulty: Lead-free materials may pose greater challenges during processing, potentially requiring higher technical expertise.

In conclusion, the choice between lead-containing and lead-free welding materials depends on the manufacturer’s prioritized factors, including cost, environmental consciousness, and concern for product safety. An increasing number of manufacturers are leaning towards using lead-free materials to meet consumers’ demands for safety and environmental responsibility.

The Problem With Lead in Manufacturing

Even if the cup or bottle remains undamaged and there is no direct exposure to lead, the presence of lead in the manufacturing process poses a potential risk. EPTAC, the solder training institute, notes on its website that the lead content in solders is unlikely to cause severe health issues for consumers, but there remains a concern for workers involved in the manufacturing process who may be exposed to lead.

A representative from the Centers for Disease Control and Prevention emphasizes that when lead is used in manufacturing, there is a potential risk of lead exposure for consumers, particularly in products intended for food consumption, such as drinkware. Additionally, there is an occupational safety risk for workers, and without proper safeguards, there could be a risk for the families of these workers through take-home lead exposures.

Manufacturing Process Ensuring Absence of Lead in Water Bottles

Today’s society is becoming more and more health and environmental conscious, and Everichhydro, as a leading water bottle manufacturer, are committed to providing you with a safe and healthy lifestyle. We are proud of our production line, especially our insulated water bottle series, which is not only a high-quality insulated container, but also a health guardian in your life.

Our insulated water bottles are made with advanced manufacturing techniques, high quality materials, and most importantly, we have completely eliminated the use of lead, which is a hazardous substance. This means that every water bottle you use is 100% lead-free, providing you and your family with a safe and reliable drinking environment.

In our quest for excellence, we have always been environmentally responsible. Our lead-free water bottles not only meet your daily use needs, but are also a green commitment to the planet. By choosing our products, you not only get excellent insulation, but also enjoy a healthier and greener lifestyle.

By choosing our insulated water bottles, you are choosing lead-free, safe and healthy quality. Let’s work together to build a green and healthy future, starting with every drop of water and injecting more care and warmth into your life.