As a common drinking tool in life, seemingly ordinary insulated water bottle, but behind the hidden tens of billions of dollars of the market, and sales are still climbing year by year, from 18.63 billion yuan in 2016 to more than 28 billion yuan in 2021. With the national health awareness and living standards rising, coupled with intelligent, personalized, energy-saving, and environmentally friendly demand, the market size of insulated water bottles will be further expanded.

The insulation effect of stainless steel water bottles is better, which has many excellent characteristics. Stainless steel vacuum insulation vessels are welded together with the inner liner and outer shell, and the sandwich is pumped into a vacuum to achieve an adiabatic insulation effect. Stainless steel material itself has excellent stainless corrosion resistance and good resistance to intergranular corrosion. Under the consumption upgrade and process improvement, insulated water bottle is given more characteristics.

With the improvement of the consumption-ability of the residents, consumers have put forward higher requirements for the appearance of the thermal water bottles, the degree of customization, fashion, technology and intelligence, and product quality. The high plasticity of stainless steel material makes it easy to shape and other excellent characteristics for product design to create a broader space to play. In recent years the manufacturing process is also gradually improved and combined with the public increasingly paying attention to environmental protection and other health factors, the stainless steel water bottle development of the times has given more product characteristics.

Although the rapid development of the wholesale insulated water bottle production enterprises brought the driving force, but also further intensified the market competition. Meanwhile, when the demographic dividend is receding, enterprises have to face the labor shortage, rising costs, and other issues. The rapid development and application of automation and intelligent technology have not only eased the dilemma of “labor difficulties”, but also further improved product quality. Our insulated water bottle factory has achieved a whole production line and flexible deployment.

Background and Technology of Industrial Robots

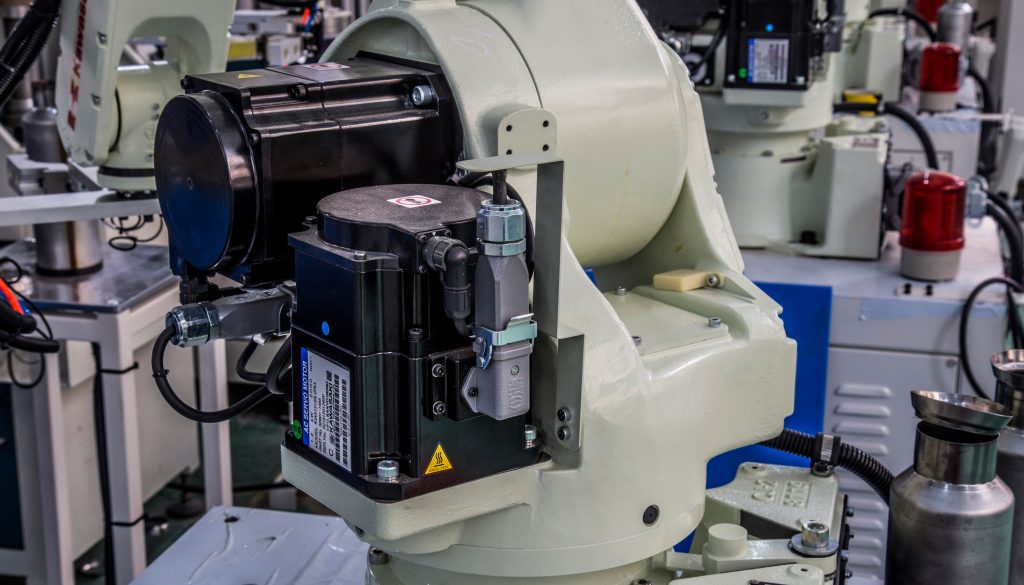

In the continuous development of science and technology, the automated production of industrial robots has become an important development trend in industrial production. It can effectively improve production accuracy, quality, and efficiency. The emergence of industrial robots has changed the production form and scheme of insulated water bottles and reduced the amount of manual labor input.

Industrial robots are multi-joint manipulators, high degree of freedom mechanical devices for industrial fields. Industrial robots are designed to improve productivity, liberate labor, modernize manipulation, and can complete industrial production, which are multi-axis linkage mechanical devices. Industrial robots with the help of network technology, sensing technology, mechanical technology, robot action, and many actions such as lifting, moving, taking, etc. are automated program control. The usage requirements are high productivity, wide working space, and a small covering area, combined with the workshop production process and requirements. The mechanical structure parts are mainly made of corrosion-resistant stainless steel, and the integration of the robot structure is strengthened as much as possible. The power is an electric drive system so that the robot can operate more quickly and flexibly accordingly. The industrial robot control is realized by computer, PLC, and other operations to ensure the accuracy of the control production.

Industrial Robot-Based Automated Production Line Solution

Industrial robot automation production line mainly includes system structure, control system, and control system. An industrial robot is a linked complex system, mainly including a sensing system, servo drive system, control system, and operation mechanism. It can be roughly divided into the control center, body mechanical structure, and drive device. The control center acts as the brain of the whole robot, stores the whole system operation process in the computer terminal, and issues tasks to drive the mechanical mechanism to operate. The drive mechanism is composed of a transmission system and power system and completes the production tasks according to the command tasks issued by the system. The robot has certain bionic parts, such as hands, hips, wrists, and walking parts. Today’s industrial robots can unfold all kinds of operations in three-dimensional space and can realize automatic operation, repeat programming, and error-proof operation. Thus it has become a trend in the field of industrial production and can complete tasks on time and with high quality.

Advantages of Insulated Water Bottles Automatic Manufacturing

- Neatness and coherence make for greater efficiency.

- Reduce manual intervention and improve production line stability.

- The finished product rate is higher, and the yield rate can reach more than 99%, which largely avoids the direct economic loss caused by steel loss.

- Highly optimized capacity, greatly reduced production time and cost.

Everich adopts a standardized production line to realize various processes including laser cup dividing, shrinking, flaring and thread rolling, etc. The industrial machine could improve line scalability and production efficiency. Besides, the whole line is faster and more productive.

For the traditional manufacturing industry, with the intensification of industry competition and the improvement of consumer demand, automation is like a black hole, no matter whether the enterprise is active or passive, can not escape the fate of automation. Only those enterprises that truly complete their own automation “revolution” can join the world’s advanced manufacturing industry.

Conclusion

With the continuous improvement of consumer consumption concept, on the basis of the original features of good thermal insulation performance, safety and portability, health and hygiene, the insulated water bottle has been gradually endowed with features such as fashionable appearance, multi-functions, scientific and technological intelligence, energy saving and environmental protection. From the basic drinking water appliances developed into different life scenarios, show consumer personalized needs, meet health quality, fashion trends, and other healthy living appliances, from the design of increasingly diversified, humanized, intelligent, appearance and style design is increasingly fashionable and exquisite.

Everich And Tomic Housewares Co., Ltd. is one of the leading stainless steel water bottle manufacturers in China. Founded in 2000, our company’s main business is the research and development, design, production, and wholesale of water bottles and food containers made of different materials. The main products include insulated water bottles, BPA-Free water bottles, tumblers and mugs, vacuum jugs, food containers, etc. After years of development, the company has now become an influential professional manufacturer of stainless steel water bottles in the industry, with excellent quality, a high degree of automation, strong R & D and design capabilities, and rich product lines compared with domestic enterprises in the same industry. After years of accumulation, the company has a relatively strong R & D design strength, the core technology advantage is reflected in the field of stainless steel water bottle design and manufacturing capabilities.

Besides, Everich also continues to optimize the existing technology, improve the automation of production lines, and strengthen the production equipment technology to upgrade, so about continuously improving product quality and production efficiency to meet the needs of domestic and foreign customers. Everich has strong R&D capability, and a certain proportion and number of new products are launched every year, reflecting our continuous product innovation and fashion attributes. Besides to the fast pace of new product launches each year, Everich products have a certain life cycle and sustained competitiveness. Moreover, our factory has a strong delivery capability, with an order-to-delivery cycle of only 3-4 months, which allows the company to meet customer demand while avoiding the impact of significant fluctuations in raw material costs. With its advanced and efficient technology and location advantage, Everich has developed an efficient delivery capability. Welcome to contact us if you have any questions.